Industries

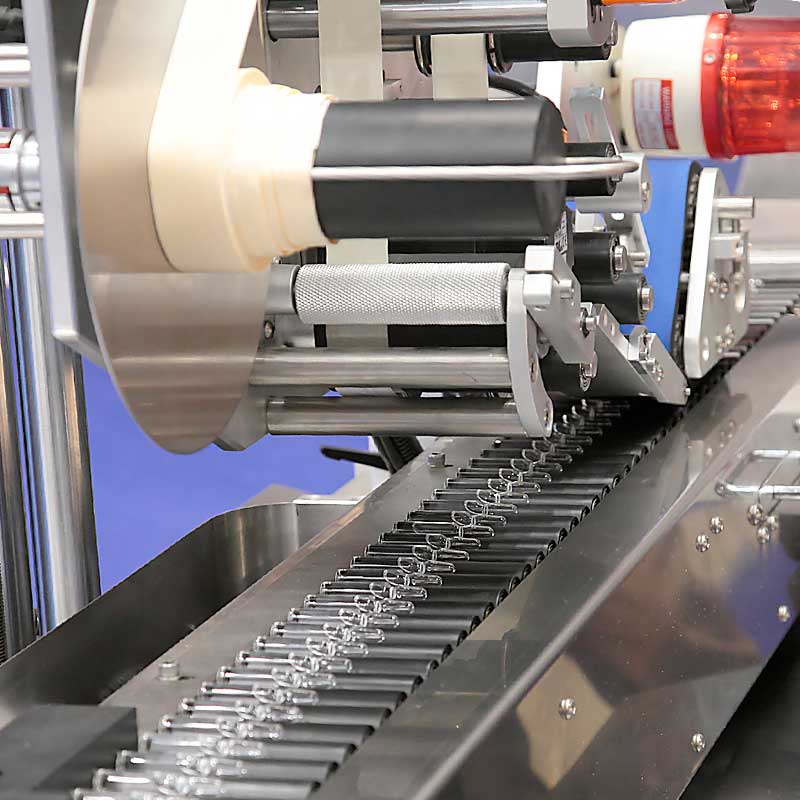

Lea Manufacturing are privileged to work with a broad range of industries throughout the world. No two customers are the same and we pride ourselves in working with people across many fields and many countries to improve the efficiencies of their production process of any finished part.

Listed below are some of the common industries we supply to, but in truth we can be useful and save money or time to anybody making ‘shiny’ or ‘smooth’ objects.