Our Product Ranges

Our specialities are in the design and production of polishes for professionals.

Lea Manufacturing's knowledge spans back over many decades helps us to ensure the most cost effective solutions for the finishing processes that industrial production lines require but also the best solutions for bespoke craftsmen.

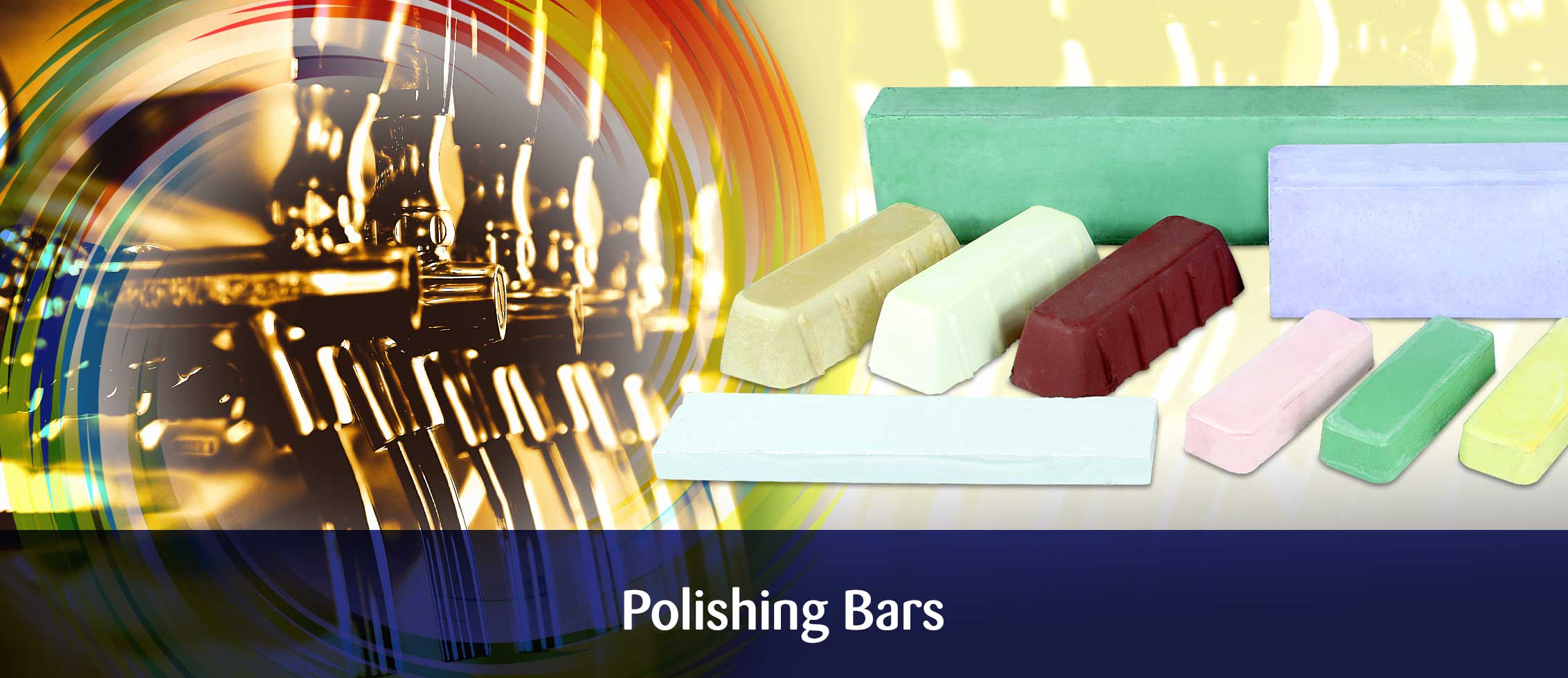

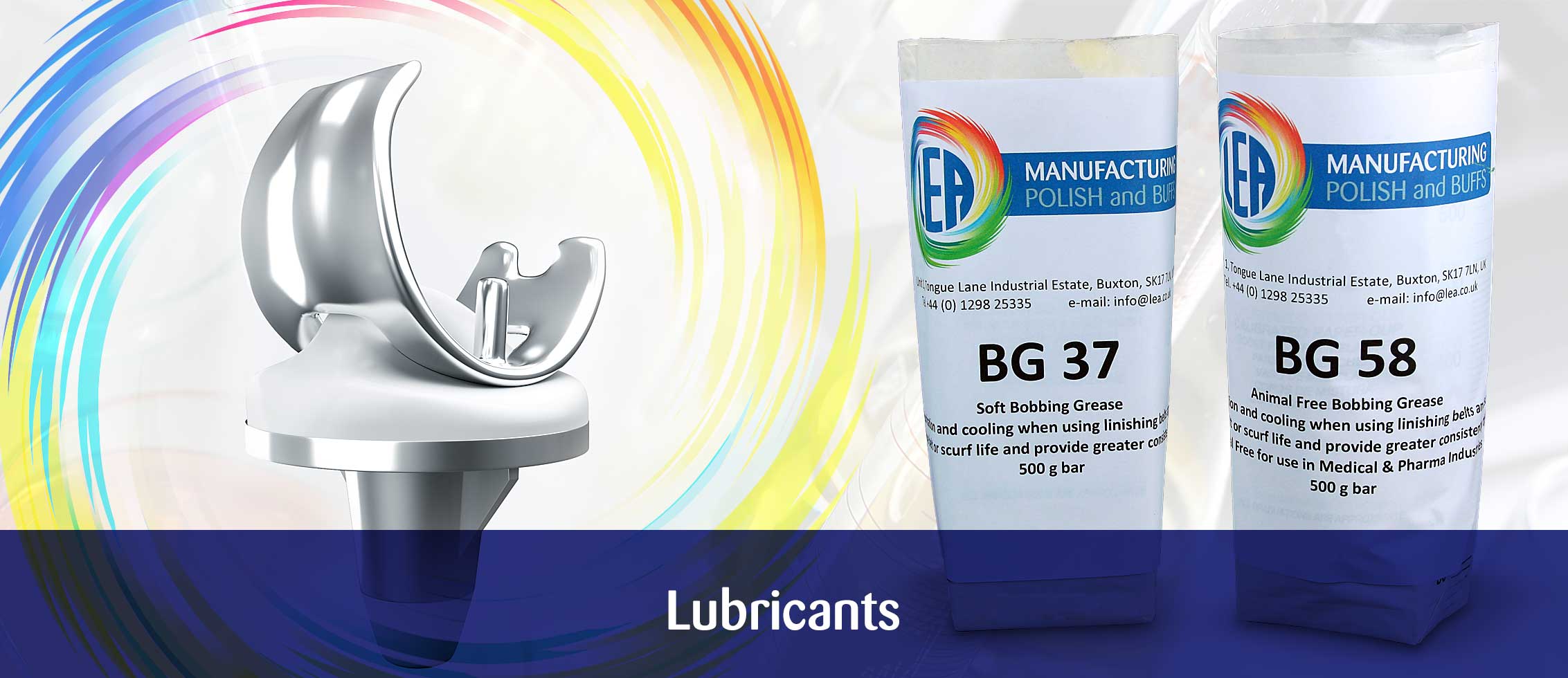

Our different product ranges have been developed to fit into different requirements of many industries.

Take a look at our list of products below to find out more about each of them.