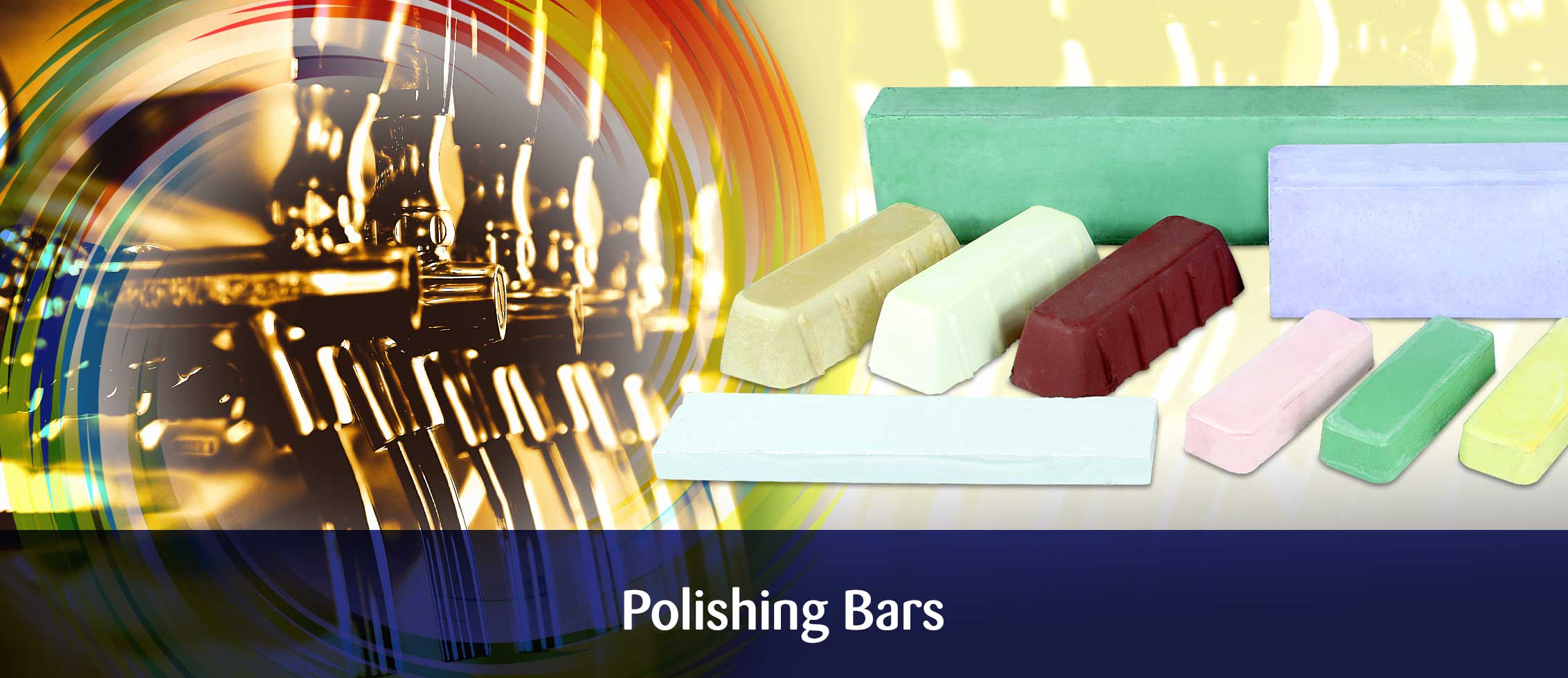

Grease Bars

Polishing bars also known as grease bars are the most efficient way of heading up polishing mops.

They can be used for bright finishing, colouring, buffing, high lustre or mirror polishing, but also for prepolishing and when metal removal is as important as reflection.

Binder systems blend vegetable and animal greases with refined paraffin waxes allowing the required lubrication, hardness and mop adhesion for the application. They are developed to be easily saponifiable reducing issues in downline processes such as cleaning and plating.

Grease Bars are the usual polish in manual polishing applications.

Our industrial size is 8” x 2” brick (200mm x 50mm) which is around 750 – 850g.

In some grades we also do 4” (100mm x 25mm, 100g) or 5” (125mm x 40mm, 300g) for applications where small bars are more suited.

The bar is applied to the rotating mop, the frictional heat transfers the abrasive in its binder system to the head where it will be able to polish the part whilst being held on to the head.

The binder system used is specifically designed for different applications. The amount of lubricity needed and mop adhesion depends according to material and rake.

Some automatic applications use bars that are fed onto the head by a special bar applicator. The advantage of bar in these situations it can give a more even head build and produce less mess.

For automatic applications bar sizes can be whatever is desirable to the application.

Below is a list of our commonly available products - View Table >